I recently picked up a Küat Sherpa 2.0 hitch mounted bike rack. My slatwall

enhanced garage provides the perfect means for storing it when not in use.

Fabrication

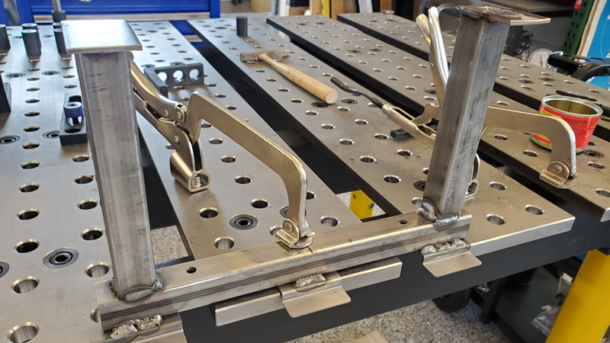

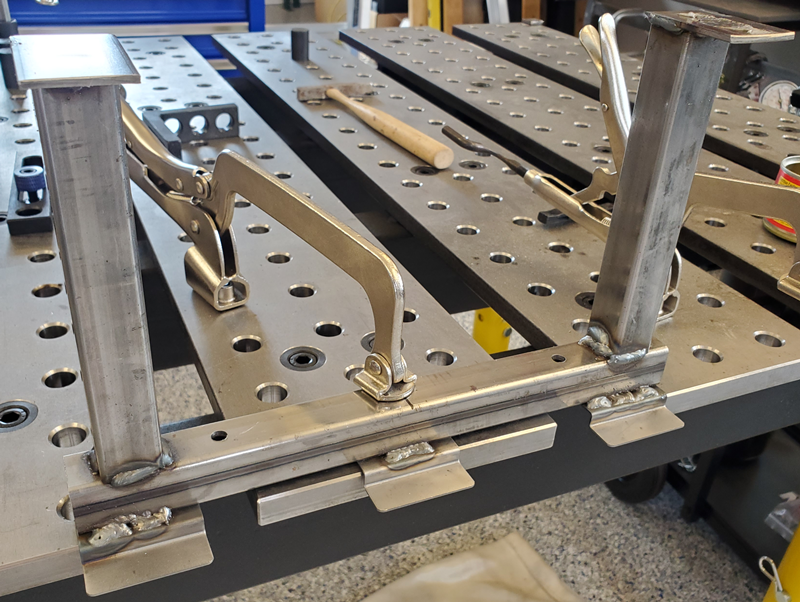

Using some scrap 1×1 square tubing, a pair of hanger arms were welded up.

It simply needed to be deep enough to hold the rack, with end caps to prevent it from slipping off.

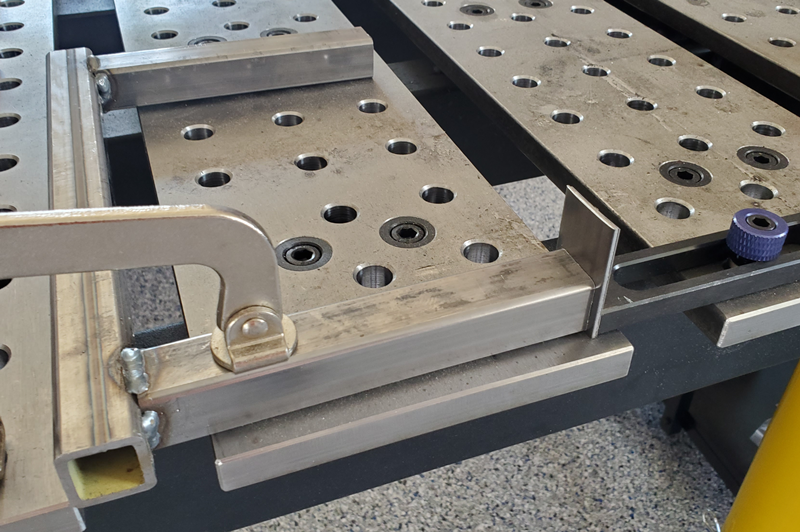

I picked up some slatwall metal plate mounts from Store Fixtures Direct. These are handy for making your own slatwall mounts.

Align them carefully before welding, to ensure the mount hangs true. Since the bike rack weighs 32 lbs, I used 3 plates to spread the load.

Once welding is done, clean the piece up with brake cleaner and then paint.

Lastly, I glued a couple of strips of neoprene on to keep it from scratching the rack.

Works great. Hanging the rack in this orientation keeps it close to the wall to minimize load on the hanger.